Aerolineas Argentinas, vaccines and the logistical complexity of the «We’ll See» approach, Part 1 bis: The dry ice dilemma

A very common question that I often run across is the differences game: why if one plane brings 400,000 vaccines, another one brings 2 million. And another one brings 1.5 million. And the one over there brings 3 million. And the one from there brings 700,000. And this one from DHL brings 10,000. And that one 40,000.

The basic answer is: because you are comparing apples and oranges. And in this note, we are going to elaborate on what is a pear and what is an orange.

In the lengthy Part 1 of this series, you’d think we’d have covered all aspects of freighter vs. owned aircraft. But we didn’t. Something was missing, and it was deliberately left out so as not to confuse.

Another issue to consider is the vaccine packaging and its cold chain requirements. And if part 1 was about math, part 1bis will have some chemistry involved. All right, you can leave the article now if you wish. I won’t be offended.

There are three basic parameters to be taken into account when transporting vaccines in production: weight, packaging volume (we already noted that the container is not heavy, but large), and cold chain requirements.

And these last two parameters converge in one factor: the greater the cold requirement, the greater the volume of the cargo to be transported. Let’s see then, the three main groups of vaccines, separated by their conservation requirements:

Group 1: -80°/ -60° (Pfizer/BioNTech).

Group 2: -25°/ -15° (Sputnik V, Moderna)

Group 3: 2°/ 8° (Astra Zeneca/ Sinovac /Coronavac)

Obviously, the requirements of Group 1 make the maintenance of this cold chain much more complex than Group 3. In order to transport with a stabilized temperature for a predictable period of time between leaving the factory and arriving at the point of application, the transportation must be done with a key element in this story: dry ice.

Dry ice has nothing to do with ice cubes, even if more than one ice cream factory sends in its delivery some small pieces (and while talking about it, for reasons that I will explain below, you should never in your life eat one of those, or hand them over to a minor, or to an adult who has no idea what it is and how it is). It is Carbon Dioxide (CO2) in a solid state.

When dry ice approaches -78.5° it does not melt but rather sublimes. It does not change one desire for another, but changes from a solid to a gaseous state without passing through the liquid state of matter. That is to say that CO2 is now an odorless gas, which in the usual concentrations is not dangerous. But its accumulation in an aircraft becomes a major and potentially deadly risk.

High concentrations of CO2 can cause breathing difficulties, asphyxiation, and, consequently, death. Therefore, it must be treated as dangerous goods, with specific regulations for its transport and use onboard.

I have already given you three facts: the temperature of the vaccines, what is dry ice, and that there are regulations for its use and transport. Let’s elaborate on that then.

The maximum amount of dry ice to be transported on a flight, whether passenger or cargo, is determined by the aeronautical authority to which its operator reports, without prejudice to that operator’s more restrictive criteria.

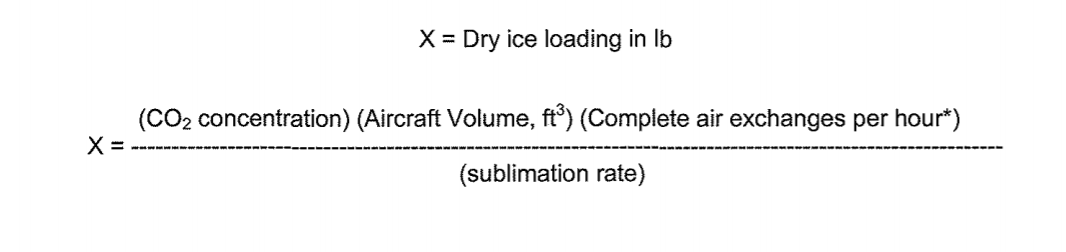

The FAA applies a formula to determine this amount. But it is far from uniform:

The sublimation rate of 1%/hour for large (50 kg or more) CO2 packages and 2%/hour for smaller packages.

The CO2 concentration is a relatively known value: one kilogram of dry ice will sublimate at 0.50m3.

The other known fact is the volume of the aircraft, and the last value is the one that spices things up. This is because it refers to complete air refills per hour, which depends absolutely on the capabilities of the air recirculation system of each aircraft, which changes between models and variants, upgrades, conversions, and a long list of so forth and so on.

Besides the difference in aircraft type and model, there is also the operational equipment of the particular aircraft to be flown: whether or not it has sufficient carbon dioxide detectors, whether it has supplemental oxygen for the crew, whether it carries passengers or personnel outside the cockpit, whether it does not have any deferred items from the temperature control/air recirculation system, and so on and so forth.

In response to the need, more than one government is taking action: in early December, South Korea increased the maximum dry ice carrying capacity from 3,300 to 11,000 kilograms in order to carry more vaccines per flight, requesting the installation of additional CO2 detectors. It is to be expected that other aviation authorities will take exceptional measures if the circumstances require it.

To conclude: with one exception that I will mention later, not all aircraft can be filled with vaccines from boat to boat. Because they would exceed the limit of dry ice on board.

To show this, one of the companies we approached for the first part of this series, and which provided us with a well-average quotation, proposed a Boeing 747-400F but limited to 50 tons. If we retake the 9408 kilograms of the 300,000 doses brought in on the first Aerolíneas Argentinas’ flight, we are talking about 1,594,388 doses.

As I said before, there is only one aircraft in the market capable of operating without a dry ice limit, and that is the Antonov An-124. Technically, because of its constant air recirculation system, but also, because there is no way that you can fill that airplane’s hold with CO2. Not even to the 225, but so far I don’t think anyone has even dared to measure it.

These limitations, as we said, vary according to a huge number of factors. ANA Cargo, for example, limited all its freighters to 1300kg of dry ice, regardless of the volume of the aircraft. This limit is also worked out with the manufacturers, who update the quantities as they meet the different requirements of the operators. The FAA authorized United to carry more than 6000 kilograms of dry ice, but on specific flights (Pfizer Chicago-Brussels logistics bridge) and on specific aircraft.

Clearly, the sublimation rate, indicating degradation based on hours, affects more long-haul flights, and even more those that are non-stop. So – and as the 50-tonne product limit reveals – in a logistics train such as Russia-Argentina, or India-Argentina, or South Korea-Argentina, it will be more relevant than in an intra-European vaccine transport.

Finally, an important detail: the more cold required for the conservation of vaccines, the greater the amount of dry ice that this packaging requires. So when we compare 100,000 Pfizer vaccines with 300,000 Sputnik V or 2 million Coronavac, we have to take into account that the former needs 23 kilos of dry ice per 5,000 doses, the latter uses a combination of cold gel and dry ice, and the former requires almost nothing.

This is how we determined that the cold needs of each vaccine are an important part of all the factors that will ultimately determine the logistical complexity of its transportation. Moving a Pfizer at -70° is not the same as moving a Coronavac at 8°. Once we are clear on this, we will see that pears are one thing, oranges are another.

Para comentar, debés estar registradoPor favor, iniciá sesión