Company proposes aircraft towing system using underground rails

Aviation contributes approximately about 2% of global greenhouse gas emissions, a percentage that the Air Transport Action Group forecasts will increase without a shift to sustainable fuel (SAF). However, to one company, sustainable fuels are not the only way to address aviation fuel use and emissions.

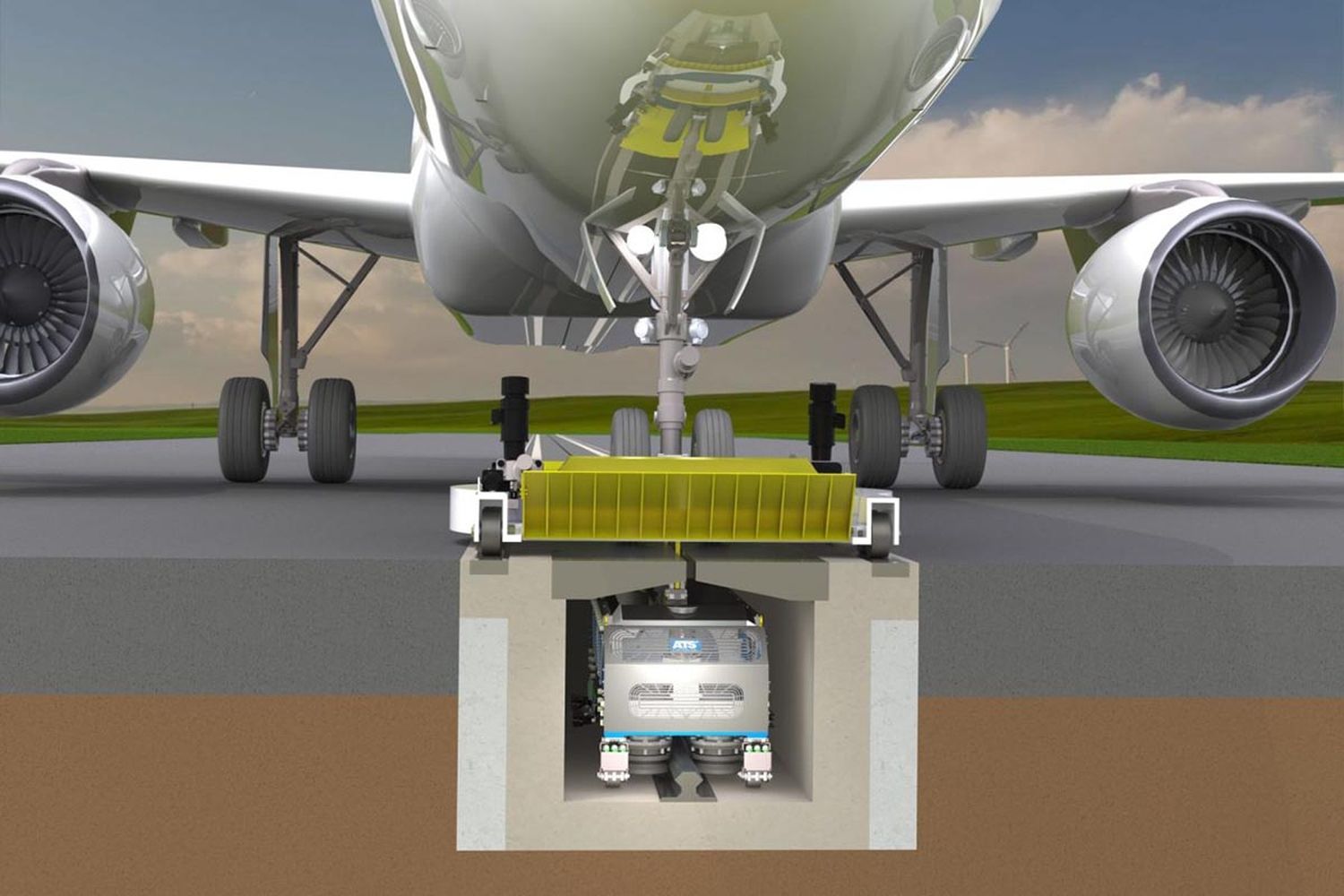

At Aircraft Towing Systems World Wide (ATS), a new system addresses the problem from another perspective. The Oklahoma-based company has developed a concept that uses electric winches that travel along below-ground tracks on airport runways and taxiways to pull aircraft to and from the terminal. ATS has been testing a prototype at Ardmore Industrial Airpark in Oklahoma since mid-year.

According to Vince Howie, ATS’s innovation provides the potential for environmental savings and compliance with future emissions limits. The project is also on schedule. The European Union Aviation Safety Agency (EASA) has already published objectives for engine-less taxiing by 2050. Ultimately, the Federal Aviation Administration (FAA) will do so as well.

Big savings

Boeing 737s and Airbus A320s account for about 80% of the commercial aviation fleet and burn about 9 gallons of fuel per minute during taxiing, with an average taxi time of 16 to 27 minutes. Aggregated to that, when operating at normal capacity, an average large commercial airport could see this flow 800,000 to 900,000 times a year.

«If an aircraft uses 9 gallons of fuel per minute for 16 minutes, 800,000 times a year, and fuel costs $2 to $3 a gallon, you’re talking real money», says Howie. » The savings our system will offer are huge», he adds, pointing out that the system not only saves fuel but also reduces emissions. Pilots can shut down the engines while the electric trailers pull the aircraft.

«Emissions are reduced by up to 80% by shutting down the main engines», he says. «The APU is the only thing that keeps running to power the air conditioning and the crew and passengers».

Shutting down the engines also reduces noise. «The noise reduction is immediate and the reduction is tremendous when you turn the engines off,» Howie adds. «Our system also reduces collisions because we track as we move aircraft into the terminal».

The ATS system also reduces engine maintenance intervals because pilots shut down aircraft engines on the ground. «This provides incremental savings», he says.

Building a Prototype

When the COVID-19 pandemic broke out ATS began work on its prototype. However, the situation delayed the project for nearly a year, but ATS finally broke ground on January 14, 2021, and began construction of the test area at Ardmore Industrial Airpark.

The modular design of the system allowed construction teams to install pre-manufactured sections. Installed sections become operational immediately.

Once completed, the ATS will use an electrically powered subway trolley and an above-ground tow platform to traverse the U-shaped channel to move aircraft to and from airport runways and gates without relying on aircraft engines. A 400-horsepower Borg-Warner electric motor, used in electric cars, powers the trolley and tow dolly.

ATS purchased a 727 to demonstrate its innovation in towing.

How the ATS system works

Howie describes the ATS system as a modern rail system for aircraft. The tow car sits on a monorail at the bottom of the canal, which is underground. Two sets of hydraulic motors, one at the front and one at the rear, move the carriage.

When landing an aircraft, pilots roll onto the taxiway and drive the nose wheel of the aircraft onto the ATS trailer, resembling a round disk with ramps at each end. This secures the aircraft in place.

«When that happens, the main engines are shut down and the trailer does the job», Howie says. «A round tow car never puts pressure on the nose landing gear. There is positive control of the aircraft. The system can pull or push the aircraft in different directions, but the pilot maintains control». A foot of snow or an inch of ice makes the system work.

By designing a roll and rollback system, Howie explains, ATS has expanded the product’s scope.

«We were aiming for 34 airports in the U.S. for the total system; hubs like Dallas or O’Hare and places like that», he says. «But we had 22 smaller airports that said they needed an electric pushback system, so we developed a curved rail that allows us to bring an airplane in and turn it around as we push it back. Approximately 200 U.S. airports could benefit from the pushback system».

The system uses vehicles capable of handling regional-sized aircraft up to an A380. Whether the ATS system will be part of the decarbonization trend will depend on the future and the orders placed.

Comentarios

Para comentar, debés estar registrado

Por favor, iniciá sesión