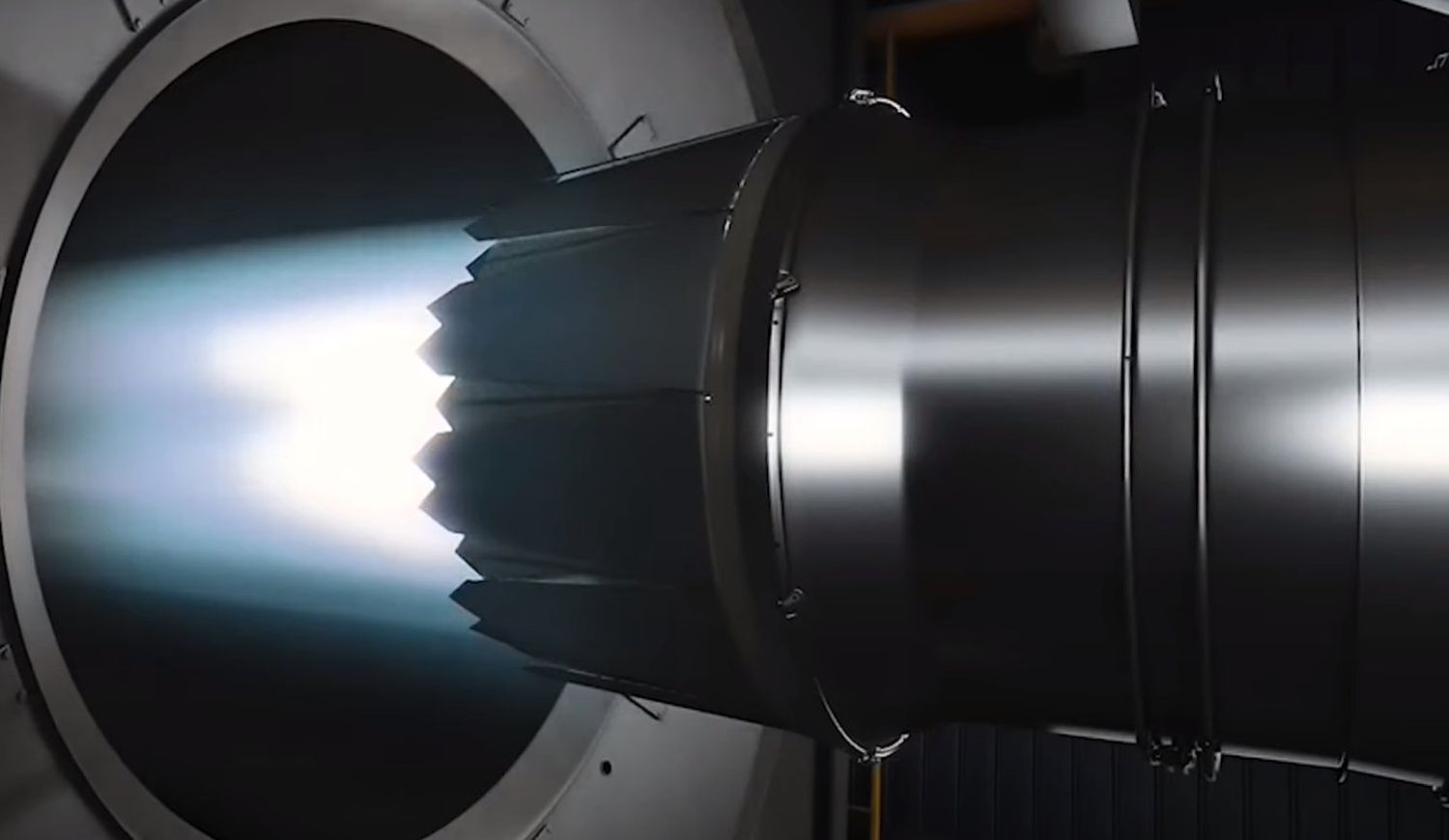

On March 25, the U.S. Air Force and GE began Phase 2 testing of GE’s second XA100 adaptive cycle engine at the U.S. Air Force’s Arnold Engineering Development Complex (AEDC). This milestone marks the first test of an Adaptive Engine Transition Program (AETP) engine at AEDC.

“AEDC’s advanced testing facilities are a unique national asset. We’re thrilled to begin testing here and continue maturing this propulsion system that we believe represents the future of the F-35,” said David Tweedie, GE Edison Works’ general manager for Advanced Combat Engines. “Our testing to date has validated the XA100’s transformational capability, and we’re looking forward to seeing the performance data from Phase 2 testing.”

GE completed Phase 1 testing of this XA100 test engine in November 2021 in Evendale, Ohio (nearly a year of testing). As GE’s press release reports, Phase 2 testing will be conducted entirely at AEDC, representing the culmination of the AETP and signaling readiness to transition this technology to full-scale development.

GE’s XA100 became the world’s first ever flight-weight, three-stream adaptive cycle engine in December 2020 before initiating tests on its second engine in August 2021.

GE’s XA100 adaptive cycle engine is positioned to deliver game-changing capability to the F-35.

Why this engine, and why now? Here's an explainer. ⬇️ #XA100 #F35 pic.twitter.com/NR2MwVIgoo

— GE Aerospace (@GE_Aerospace) February 14, 2022

GE’s engine is uniquely designed to fit both the F-35A and F-35C without any structural modifications to either airframe, enabling improved aircraft range, acceleration and cooling power to accommodate next-generation mission systems (like laser weapons), while ensuring better durability and higher availability.

“The XA100 simultaneously provides transformational improvements in fuel efficiency, thrust, power, and thermal management that simply cannot be matched by legacy propulsion systems,” Tweedie added. “These improvements will help ensure the F-35 remains a preeminent fighter platform not just in the near-term, but for decades into the future, and will enable lower operational and sustainment costs for the services».

Improvements in all indicators

The XA100 combines three key innovations to deliver a generational shift in combat propulsion performance:

- An adaptive engine cycle that provides both a high-thrust mode for maximum power and a high-efficiency mode for optimal fuel economy and loiter time

- A third-stream architecture that provides a step-change in thermal management capability, enabling future mission systems for greater combat effectiveness

- Extensive use of advanced component technologies, including ceramic matrix composites (CMC), polymer matrix composites (PMC) and additive manufacturing

These revolutionary innovations increase thrust by more than 10%, improve fuel efficiency by 25% and provide significantly greater aircraft heat dissipation capability, all within the same physical envelope as current propulsion systems.

The XA100’s improved fuel efficiency and provides a significant reduction in carbon emissions and will operate on any sustainable aviation fuel approved by the U.S. Air Force.

A cost issue

Adaptive-cycle engines will eventually become a reality, because in addition to equipping future F-35 aircraft blocks, they are going to be the powerplant for the USAF’s and USN’s new sixth-generation fighters.

But despite promises of performance improvements and lower operating costs from the adaptive cycle engines currently under development, the option of re-engining the current F-35 fleet with them may be too expensive.

While General Electric states that its XA100 can be used on the F-35A and C, it does not discuss the B model, which should continue to rely on the current Pratt & Whitney F135s, which would call into question the future availability of the Bravo, vertical-landing version of the F-35.

Comentarios

Para comentar, debés estar registrado

Por favor, iniciá sesión