Maintenance Data Digitalization: TrustFlight aims for more efficiency with less paper

In the digital era, the most complex issue is not obtaining data, but what to do with it. The volume of information is such that the main need is to have processing and analysis tools.

And if to all this is added the fact that this capacity exists in real time, the user of a system with these characteristics has a considerable competitive advantage. Commercial aviation is no stranger to this philosophy, although certain regulatory issues are sometimes rooted in traditions that detract from the dynamism of an industry that depends heavily on said fast pace.

We talked about all this some time ago with Karl Steeves, CEO and co-founder of Trustflight, in a conversation that was much broader than the software itself.

Aviacionline: TrustFlight seeks to break a decades-old management paradigm: everything on paper and fivefold. How is this done?

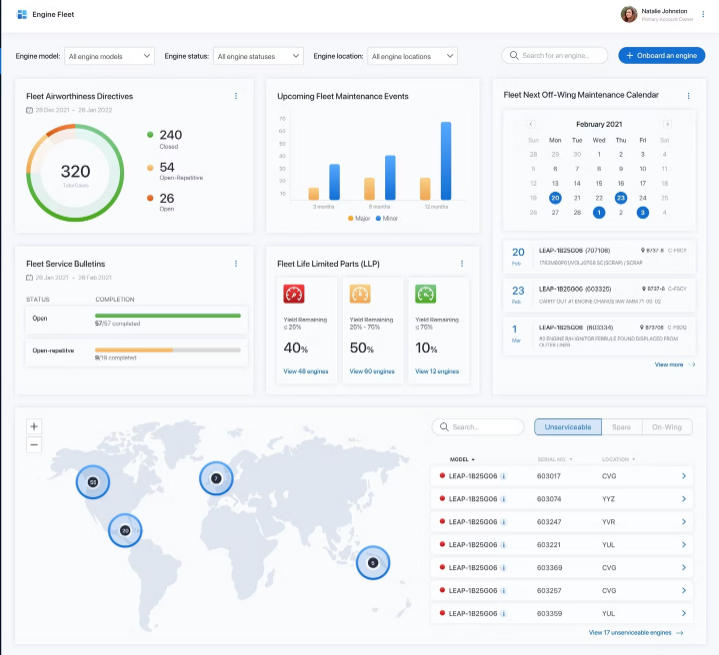

Karl Steeves (KS): It seems difficult, doesn’t it? There are digitization initiatives, but they all end up with the same thing: outdated processes that don’t communicate with each other. It’s not so much about replacing paper with a proprietary software solution as it is about thinking of a comprehensive suite that can take advantage of the tons of data that each part of the process generates.

Aviacionline: The big point is the granularity of that data. You can generate a lot of data, but if you can’t classify it…

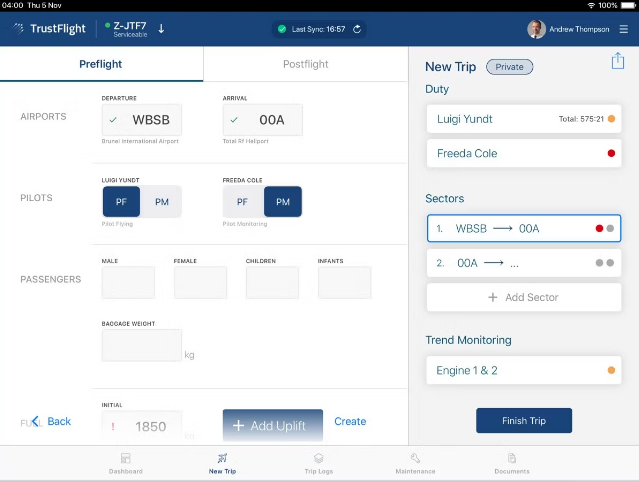

KS: Absolutely. That’s why behind the user interface design is a similar amount of pilot and maintenance technician hours as the programmers. Without that invaluable end-user feedback, we couldn’t deliver the product we have.

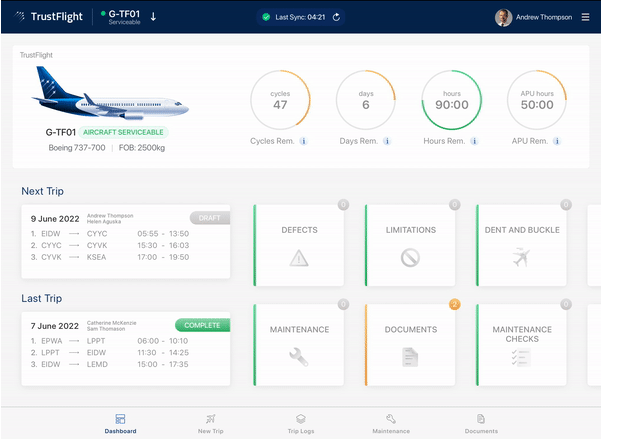

The key was to make it similar enough to what we know today to make the implementation as transparent as possible, but with real-time granularity capabilities that paper does not and cannot give.

In the traditional system, the captain signs a log 25 times, and 5 copies circulate. One stays in the aircraft, one goes to the archive, one goes to the aviation authority. In the end, a data entry system passes everything to a database. It all adds up to weight, space, physical and virtual storage: it’s all money.

But more importantly, all of that is time. If you make the effort to have an accurate and up-to-the-minute turnaround and utilization time, why waste time filling out paperwork? How many hours a year do you waste signing forms?

Aviacionline: I understand, but at the regulatory level there is still a long way to go to eliminate paper records. Do you see that change in basic assumptions far away in the strictly legal area?

KS: I don’t think so, but there is an intermediate solution: to generate the whole internal circuit through TrustFlight and print a copy for the aviation authority with the same characteristics as the current ones. It is not difficult, nor impossible: you just must get the implementation right.

Aviacionline: We talked more precisely about Aircraft Tech Log, but the suite is more complete, including an SMS solution. There are other Electronic Flight Bags initiatives already widespread in the industry: how do they complement TrustFlight products?

KS: That’s true, there are several EFB products on the market, but they look more at the pilot than the company. The different modules we have encompass all operations and seek to improve communication between maintenance, crews and the aircraft.

If everyone contributes data to the same suite, communication about an operation flows more smoothly. And if SMS is a concept that seeks to remove communication barriers so that the operation flows, it is not unheard of to think that a solution that integrates the three domains must be better than the traditional way.

Aviacionline: One question that is more it-related: who owns the data?

KS: Good question. The data always belongs to the customer. We provide the analysis and reporting framework, but the data will always belong to the operator. The solution is adapted to the regulatory framework for data processing of the user and is looked at on a case-by-case basis. The implementation is as important as the product itself.

Aviacionline: They signed with Bonza, the new Australian low-cost airline owned by 777 Partners, also controlling shareholders of Flair. In the spirit of thrift, a low-cost carrier is an almost inevitable customer, isn’t it?

KS: Actually, the very evolution of the industry makes us an inevitable product. Low-cost companies, and more so startups, have the advantage of starting from the get-go with a mindset without the «traditions» of legacies. But after integration, the technical management of an airline is similar, regardless of the business model.

The core of Bonza’s operation will have to do with Aircraft Tech Logs, but it is the CAMO (Continuing Airworthiness Management Organization) solution that will ensure efficient operations within a robust safety and compliance culture.

Aviacionline: What is TrustFlight’s vision for the future?

KS: We aim to become a solution provider that brings security and efficiency by eliminating redundancies in processes that have not been reviewed and have been the same for decades.

While process consistency has been improving, many of these little idiosyncrasies have become entrenched in all industry players as if they were immutable. And we believe that innovation can be safely achieved by vastly improving these issues the moment we stop thinking of them as carved in stone. Or written on paper, fivefold.

/https://aviacionlinecdn.eleco.com.ar/media/2022/12/20221129-blog-engineer-ux.jpg)

Para comentar, debés estar registradoPor favor, iniciá sesión