GE Aerospace Completes Key Milestone in XA102 Adaptive Cycle Engine Development

GE Aerospace's XA102 engine has passed a key phase in the NGAP program and is now moving toward full-scale demonstration.

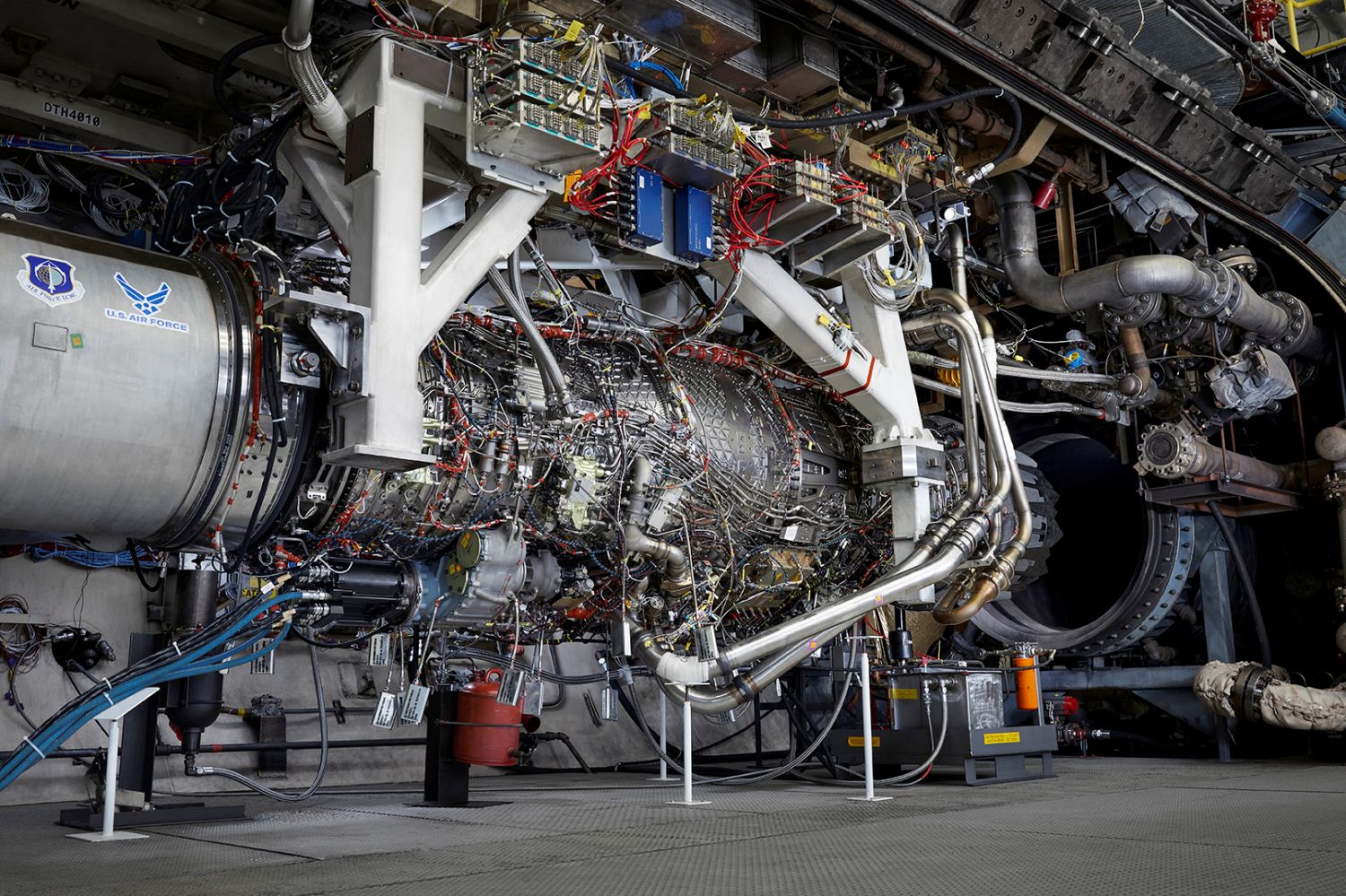

GE Aerospace has successfully completed the Detailed Design Review (DDR) for its XA102 adaptive cycle engine, marking a significant milestone in the U.S. Air Force (USAF) Next Generation Adaptive Propulsion (NGAP) program. Following this achievement, the company has secured a new contract for the procurement, assembly, and testing of a full-scale demonstrator engine.

The XA102 is the first engine in GE Aerospace’s history to be developed using Model-Based Systems Engineering (MBSE), a transformational approach in the design and testing of advanced propulsion systems. The design review, presented to the USAF, showcased a comprehensive digital model of the engine, validating its readiness for the next phase of development.

"GE Aerospace is making significant strides with Model-Based Engineering, which has been instrumental in the successful design of the XA102 engine," said Dr. Steve “Doogie” Russell, Vice President and General Manager of Edison Works at GE Aerospace. "As we move into the acquisition and manufacturing phase, we will continue leveraging this innovative approach while closely collaborating with our supply chain partners to advance the engine toward full-scale demonstration."

Next-Generation Propulsion

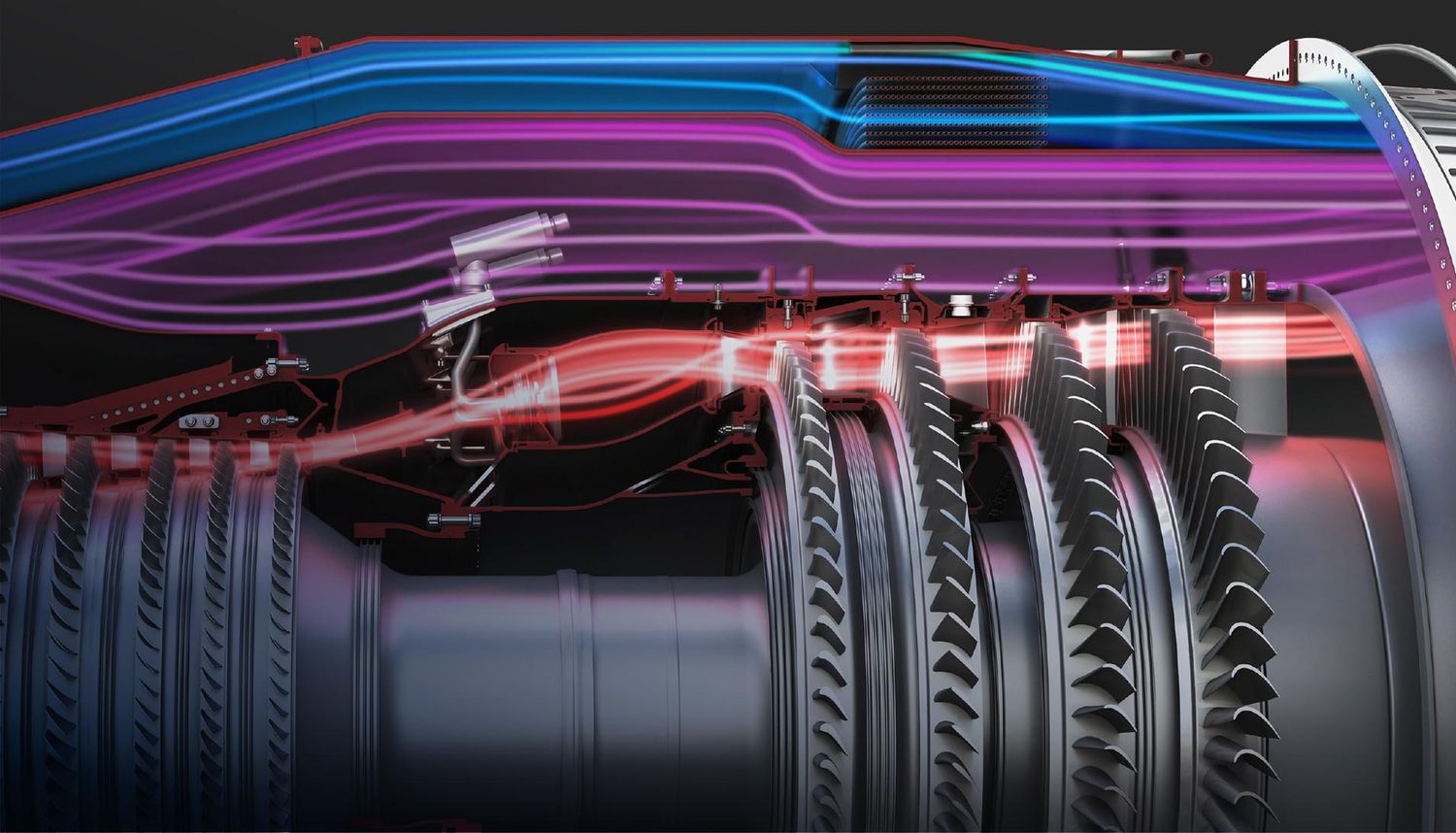

The Pentagon considers the development of adaptive cycle engines essential to maintaining technological superiority in future fighter aircraft. These engines offer up to 30% greater range and significantly improved thermal management capabilities compared to current fighter jet engines. Their ability to switch between high-thrust and high-efficiency modes allows for optimized performance based on mission requirements.

A key advancement of this new engine generation is enhanced thermal management for onboard electronic systems. The integration of a third airflow stream enables more efficient heat dissipation, which is critical for directed energy weapons, such as lasers, that require greater thermal regulation than current engines can provide.

Competition in the NGAP Program

Five companies are competing in the NGAP program to become the manufacturer of the engines that will power the USAF’s sixth-generation fighter jets, currently under development as part of the Next Generation Air Dominance (NGAD) program.

NGAP is driving key manufacturing technologies and capabilities that will enhance the range, survivability, and thermal management of future fighter jets—critical factors for integrating advanced weapons and sensors.

From XA100 to XA102

GE Aerospace appears to be leading the race in adaptive propulsion development, thanks to experience gained with its XA100 engine, the precursor to the XA102. The XA100 successfully completed multiple rounds of testing, helping mature key technologies.

The XA102 represents the next evolution in adaptive propulsion, integrating enhanced capabilities while focusing on affordability and sustainability—two critical factors for its adoption in future USAF fighter programs.

Comentarios

Para comentar, debés estar registrado

Por favor, iniciá sesión